Cape Canaveral's Trusted Non-Destructive Pipeline Testing

“With our cornerstone founded on Christian values, we strive to exceed our customers expectations while maintaining the highest industry standards, providing safe working environments, and respecting the dignity of every employee. We believe this allows our team to better serve our industry as a company and as individuals.”

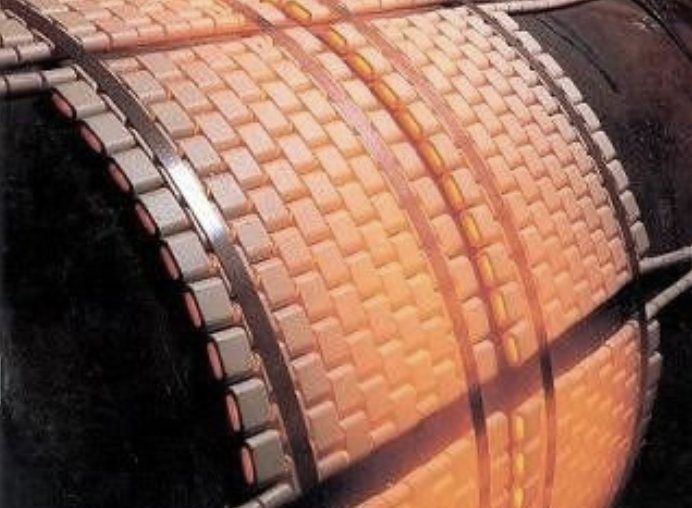

Precision Non-Destructive Testing For Pipeline Integrity Assurance

Looking for top-notch non-destructive testing for pipelines? You’ve come to the right place. At Cornerstone Industries, we specialize in providing reliable and thorough non-destructive testing for pipelines that meet your industry’s stringent standards. Our team, made up of Shell and API certified inspectors, employs advanced methods such as Ultrasonic Testing and Magnetic Particle Testing to help ensure the safety and integrity of your infrastructure. We proudly serve the Cape Canaveral area, utilizing innovative techniques to address complex inspection challenges. Partner with us today for precision and professionalism in every project. Reach out to learn how we can support your pipeline inspection needs.

Non-Destructive Evaluation and Examination Experts with Integrity

We specialize in both non-destructive evaluation and non-destructive examination to provide a full picture of structural integrity. These advanced methods allow us to assess internal defects, corrosion, and weld quality without disrupting operations. Our certified inspectors use calibrated equipment to meet stringent industry codes. From power plants to pipelines, we ensure compliance and performance.

Inspection Confidence Achieved with API-Certified Visual Experts

Our visual inspection services are backed by API certified inspectors who understand industry-specific standards. From welds to structural components, we identify surface flaws and inconsistencies quickly and thoroughly. Visual inspections remain one of the most cost-effective methods for quality assurance. We document every finding with clarity and precision.

Reliable Magnetic Particle and Dye Penetrant Testing

We use dye penetrant testing and magnetic particle testing to uncover surface and near-surface defects in metal components. These methods are ideal for locating cracks, seams, or laps in welds, castings, and forgings. Both tests are fast, efficient, and highly sensitive. Our inspectors are trained to deliver accurate interpretations and reports.

Precision Ground Penetrating Radar for Seamless Construction Projects

Ground penetrating radar is a safe, effective way to map subsurface utilities and structures before excavation. We use high-frequency radar systems to locate pipes, voids, and obstructions with minimal disruption. This service is especially valuable for construction and civil engineering projects. It helps you plan with confidence and avoid expensive surprises.

Why is Cornerstone Industries so popular?

(NDT) Non-Destructive Testing with Vendor Compliance Assurance

Our vendor surveillance ensures quality and compliance during equipment manufacturing or procurement. Combined with ndt non-destructive testing, we provide full lifecycle assurance from fabrication to field deployment. This reduces risk and ensures your assets meet performance standards before they arrive onsite. We act as your trusted eyes and ears at every stage.

Frequently Asked Questions

If you don't see the information you need, feel free to reach out to us.